Sawn timber Nomar

Within the Fagus Group, three members deal with the primary and secondary wood processing and production of sawn and dried conifer and deciduous tree timber of all dimensions and classes. We produce sawn timber from fir, spruce, pine, beech and oak coming from the western parts of Republika Srpska and BiH, with a high quality tradition. The climate of this area is of ideal conditions for growth of good-quality trees of supreme technical and technological characteristics. Since we have operated as a Group, responsible for the environment we work in.

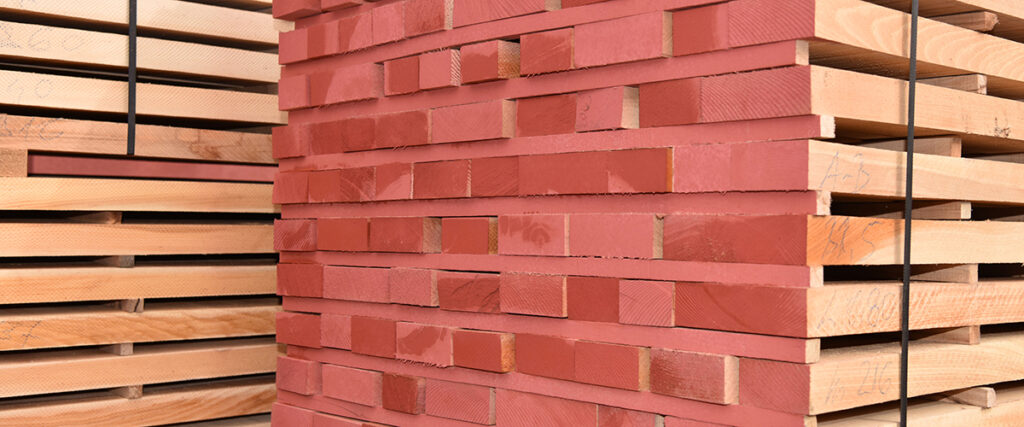

Nomar was designed as a modern sawmill for processing of thin roundwood and production of sawn fir and spruce timber of all dimensions, thickness, width and length. Prior to cutting, logs are debarked with all the bark taken off, metal-detected and sorted by its length and quality. In one cutting, the circular saw blades cut the log, which is after that transferred to the packing facility. Using circular sawblade we achieve millimeter precision of dimensions and cutting quality. We have the sawing capacity of 80,000m3 at our disposal and an automated line for packing into packages, as per customers’ requests. Thanks to the primary technical processing and good-quality raw materials, we are able to adjust our production assortment to the desires and demands of our customers.

A wide spectrum of our wood assortment consists of:

- Sawn timber of all dimensions and classes

- Timber boards of 1.5m< length

- Construction elements and smaller boards

- Other products made of fir and spruce, as per customer’s demand

Customers across the globe use our products for:

- Furniture production

- Massive panels production

- Preparation of exhibition stands

- Wall cladding production

- Interior design

- Production of auxiliary buildings

When cutting a roundwood almost 50% of wood mass goes to wood biomass (wood chips and sawdust), while the bark is removed prior to sawing during debarking of logs. Wood chips are used as energy and they can be applied directly as a product in furnaces of 50 KW to 10 MW power, while sawdust is further pressed with special pressing machines into pellet and briquette. The bark can be directly used without further processing in heating boilers, it is cheaper from both pellet and briquettes, and it is particularly cheaper than heavy oil, fuel oil and gas.

Wood biomass is efficient energy that is, in terms of price and environment, more acceptable than heavy oil, fuel oil and gas.

Contact:

Address: Gavrila Principa 19, 78 230 Kneževo, Republika Srpska, BiH

Telephone: +387 51/591-100

Fax: +387 51 591-000

Email: info@nomar.biz

Web: https://nomar.biz